Lightweight

Next-generation tech, proven today.

Carry more payload to the job site.

Bigger loads mean lower costs with each job, earning more profit with each cubic yard, day after day, year after year.

Always finish strong.

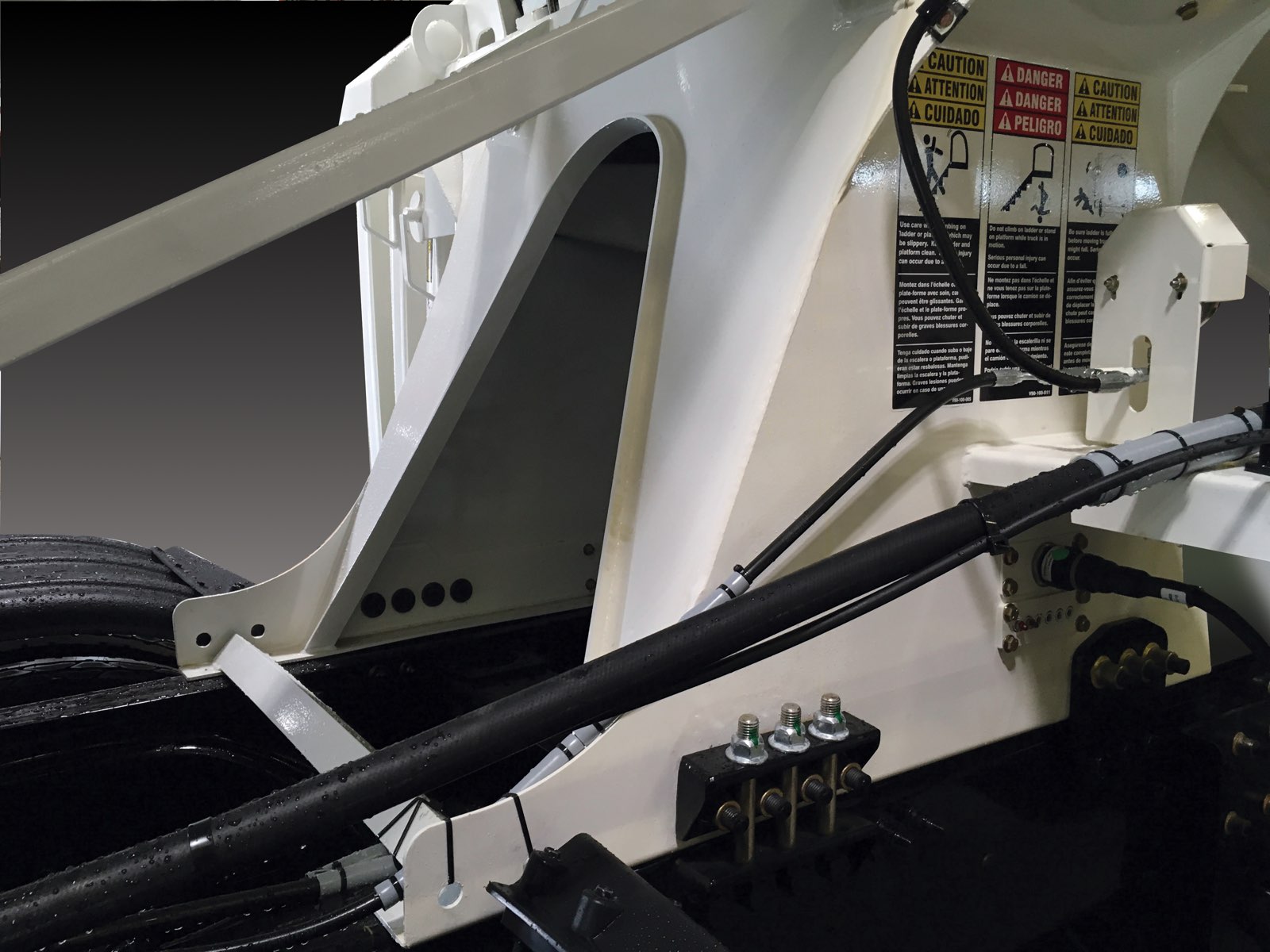

Component pre-paint process.

To save time and production cost, some competitors build complete assemblies, then paint them afterwards. However, this often leaves behind inconsistent paint finishes, gaps in paint coverage, unsightly painted hydraulic and electrical lines and more. With our component pre-paint process, we paint individual components before assembly—levers, handles, brackets and more—then we assemble the complete unit, already fully painted.

Our component pre-paint process helps ensure a better-looking, longer-lasting, higher-quality finish on all painted surfaces with more consistent coverage providing greater corrosion resistance over time. Most importantly, component pre-paint delivers to our customer the quality paint finish you deserve and puts your company image in the best light possible.

Lightweight Features

Lower Weight

Weighs 2,000 lbs. less than our conventional Express and Paver models, allowing you to carry more payload to the job site. (Based on 10.5-yard mixer comparison to 1/4-inch AR steel utilizing new ZF gearbox)

More Profit Potential

Bigger loads mean lower costs with each job, earning more profit with each cubic yard, day after day, year after year.

Proprietary Formula Steel

Made from high-strength, lightweight steel, using a proprietary formula designed specifically for concrete mixers and Continental. This steel is lighter, harder and more wear-resistant than conventional steel.

Lightweight Drum

Our Lightweight drum is only available with Continental’s Lightweight Mixers.

This Lightweight is no Lightweight

Proven toughness and durability in the harshest ready-mix environments.

New ZF CML Gearbox with Integral Hydraulic Pump

About 50% smaller and weighs 200 lbs. less than the standard ZT gearbox.